Q-FIN deburring, grinding and finishing machines gives a perfect final look to your metal workpieces. With Q-FIN you will remove the sharp edges which left after cutting, grind the surface of the material and give a final look. You will also remove slag or oxidation from laser or plasma cutting. The Q-FIN grinding machine will round the edges of the product even up to 2R. Available automatic and manually operated deburring, grinding and edge rounding machines.

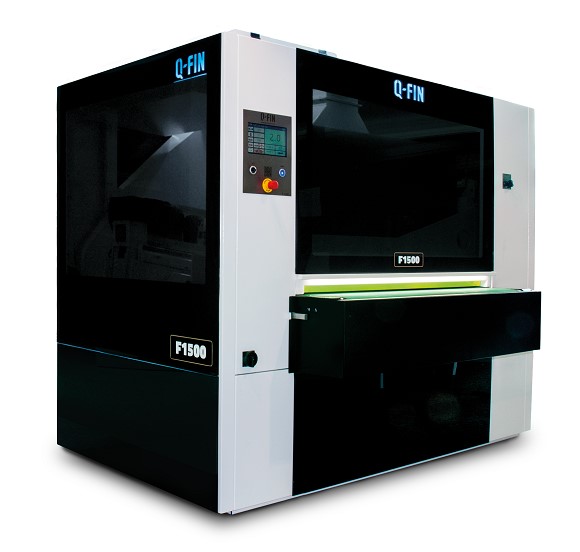

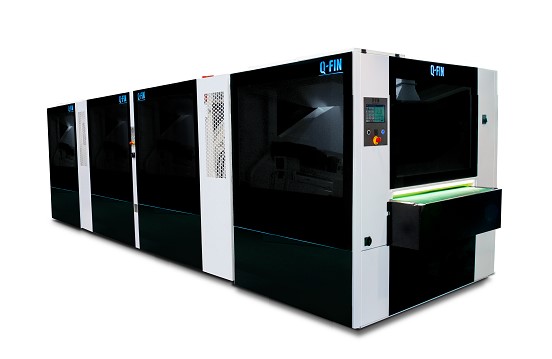

Q-FIN F1500

Finishing machine Q-FIN F1500 is built to finish large cut parts at high speed. The max width of workpiece is up to 1500 mm. Q-FIN F1500 could be equipped with magnet or vacuum support. Machine is suitable for line grain finish, slag removal, deburring, oxide layer removal, grinding, roughness grinding, edge rounding.

View a brochure: F1500

- Speed of conveyor belt: adjustable, 0,3-8 m/min

- Support: magnet / vacuum

- Min. workpiece width (LxW): mag. 50×50 mm / vac. 80×80 mm

- Max workpiece width: 1500 mm

- Max workpiece height: 170 mm

- 3 Stations: abrasive belt / 2x brush / 2x brush

- Dimensions: 2037x2478x2090 mm

- Weight: 2850 kg

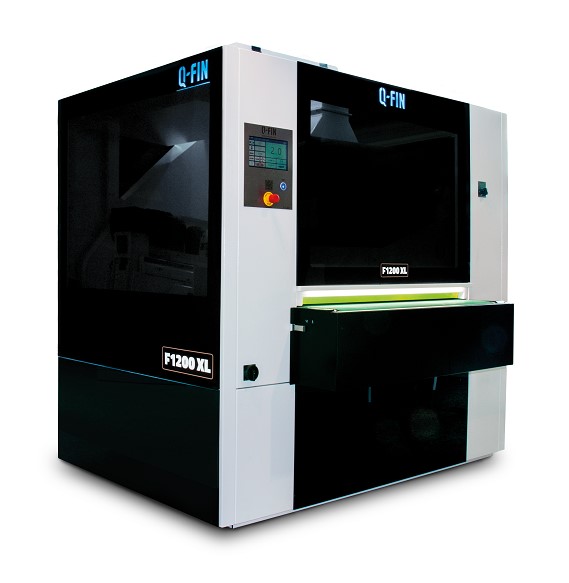

Q-FIN F1200

The grinding machine Q-FIN F1200 is a perfect choice to finish workpieces up to 1200 mm width. Machine is suitable for line grain finish, slag removal, deburring, oxide layer removal, grinding, roughness grinding, edge rounding. The model F1200 is equipped with three grinding stations, model F1200XL – with four stations, so you could be able to give a perfect look for workpieces with one machine.

- Speed of conveyor belt: adjustable, 0,3-8 m/min

- Support: magnet / vacuum

- Min. workpiece width (LxW): mag. 50×50 mm / vac. 80×80 mm

- Max workpiece width: 1200 mm

- Max workpiece height: 170 mm

- 3 Stations: abrasive belt / 2x brush / 2x brush

- Dimensions: 2040x2180x2090 mm

- Weight: 2650 kg

- Speed of conveyor belt: adjustable, 0,3-8 m/min

- Support: magnet / vacuum

- Min. workpiece width (LxW): mag. 50×50 mm / vac. 80×80 mm

- Max workpiece width: 1200 mm

- Max workpiece height: 170 mm

- 3 Stations: abrasive belt / 2x brush / 2x brush / abrasive belt

- Dimensions: 2040x2180x2090 mm

- Weight: 3050kg

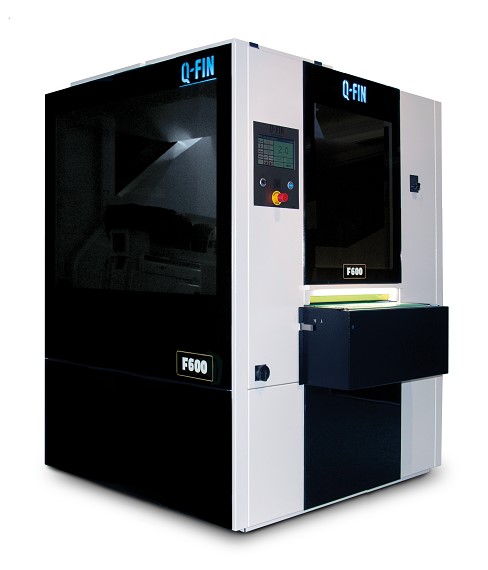

Q-FIN F600

With grinding machine Q-FIN F600 you can finish workpieces up to 600 mm width. F1200 is suitable for line grain finish, slag removal, deburring, oxide layer removal, grinding, roughness grinding, edge rounding, models SP4 and SR4 – deburring, grinding, edge rounding, roughness grinding, line grain finish. Q-FIN F600 SP4 is equipped with 3 processing stations: a grinding station followed by 2 + 2 planetary heads. Each planetary head is fitted with 4 counter-rotating bowl brushes, so the machine is equipped with 16 bowl brushes. The F600 SR4 is the rotor machine from which is equipped with a grinding device and 4 rotating round brushes.

- Speed of conveyor belt: adjustable, 0,3-8 m/min

- Support: magnet / vacuum

- Min. workpiece width (LxW): mag. 50×50 mm / vac. 80×80 mm

- Max workpiece width: 600 mm

- Max workpiece height: 170 mm

- 3 Stations: abrasive belt / 2x brush / 2x brush

- Dimensions: 2030x1585x2085 mm

- Weight: 1950 kg

- Speed of conveyor belt: adjustable, 0,3-8 m/min

- Support: magnet / vacuum

- Min. workpiece width (LxW): mag. 50×50 mm / vac. 80×80 mm

- Max workpiece width: 600 mm

- Max workpiece height: 150 mm

- 3 Stations: abrasive belt / 2x planetary head / 2x planetary head

- Dimensions: 2030x1585x2085 mm

- Weight: 2150 kg

- Speed of conveyor belt: adjustable, 0,3-8 m/min

- Support: magnet / vacuum

- Min. workpiece width (LxW): mag. 50×50 mm / vac. 80×80 mm

- Max workpiece width: 600 mm

- Max workpiece height: 150 mm

- 2 Stations: abrasive belt/rotor with 4 brushes

- Dimensions: 2030x1585x2085 mm

- Weight: 2150 kg

Q-FIN F200

For small parts Q-FIN has developed F200 finishing machine. This machine with magnet support table could finish parts up to 10×10 mm, with vacuum supply – 20×20 mm. F200 finishing machine is suitable for line grain finish, deburring, oxide layer removal, grinding, roughness grinding, edge rounding.

View a brochure: F200

- Speed of conveyor belt: adjustable, 0,3-8 m/min

- Support: magnet / vacuum

- Min. workpiece width (LxW): mag. 10×10 mm / vac. 20×20 mm

- Max workpiece width: 200 mm

- Max workpiece height: 100 mm

- 3 Stations: abrasive belt / brush / brush

- Dimensions: 1850x670x2145 mm

- Weight: 1090 kg

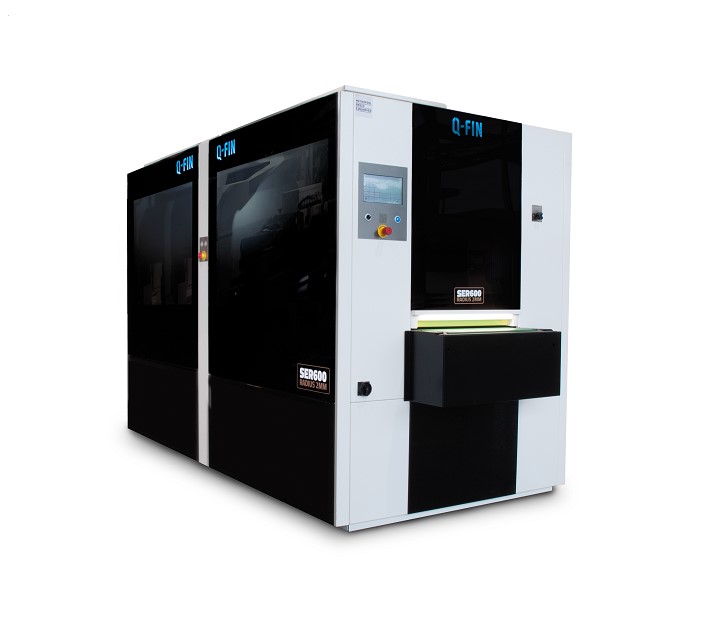

Q-FIN SER600

Q-FIN SER600 is a deburring and grinding machine with 5 processing stations: a grinding unit (1st station), 4 oscillating brushes (2nd and 3rd station), 2 round brushes (4th and 5th station). This machine could be used for edge rounding up to 2 mm radius. Machine suitable for line grain finish, slag removal, deburring, oxide layer removal, grinding, roughness grinding, edge rounding.

View a brochure: SER600

- Speed of conveyor belt: adjustable, 0,3-8 m/min

- Support: magnet

- Min. workpiece width (LxW): 50×50 mm (ferrous)

- Max workpiece width: 600 mm

- Max workpiece height: 40 mm

- 5 Stations: 1x abrasive belt / 4x disc brush / 2x round brush

- Dimensions: 3640x1585x2085 mm

- Weight: 3560 kg

Q-FIN Q2S

The Q2S turnaround station, integrated in the deburring line, provides double-sided processing in batches at an unprecedented high throughput rate. The system can be managed by one operator. The Q2S system standard includes 2 pieces of IOC input/output conveyors. Available types: 600 / 1200 /1500.

Viewa a brochure: Q2S

- Max load of conveyor: 550 kg

- Min dimensions of workpiece (L x W): 280×280 mm

- Min thickness of workpiece: 1,5 mm

- Max thickness of workpiece: 50 mm

Q-FIN DS

Q-FIN DS is automatic solution for slag removal which occurs on workpieces after laser or plasma cutting. Depends on width of workpiece there are two models available DS600 – for parts up to 600 mm width and DS1200 – for parts up to 1200 mm width.

View a brochure: DS

- Speed of conveyor belt: adjustable, 0,3-5 m/min

- Product fixation: magnet (for ferrous parts)

- Min. workpiece dimensions (LxW): 65x65mm

- Max workpiece width: 600 mm

- Max load: 100 kg

- Dimensions: 1610x1750x2079 mm

- Weight: 800 kg

- Speed of conveyor belt: adjustable, 0,3-5 m/min

- Product fixation: magnet (for ferrous parts)

- Min. workpiece dimensions (LxW): 65x65mm

- Max workpiece width: 1200 mm

- Max load: 100 kg

- Dimensions: 2016x1750x2079 mm

- Weight: 1250 kg

Q-FIN Skipjoint

SKIPJOINT is a Q-FIN machine developed to remove of micro joint which are left after laser cutting. Machine is equipped with rotating deburring disc with diameter 255 mm. With help of SKIPJOINT you can remove micro joints easier, faster, and safer than with any other grinder. Machine is suitable for micro joints removal and grinding. It can also be equipped with a (polishing) brush.

View a brochure: SkipJoint

- Motor power: 0,75 kW

- Sanding disc diameter: 255 mm

- Max workpiece width: unlimited

- Max workpiece height: 30 mm

- Dimensions: 595x405x1195 mm

- Weight: 86 kg

Q-FIN TopGrinder | ProGrinder

TOPGRINDER and PROGRINDER are manually operated grinding machines from Q-FIN. Machines are suitable for deburring, grinding, slag removal, edge rounding, roughness grinding, non directional finish, polishing.

View a brochure: TopGrinder | ProGrinder

- Max workpiece width: 780 mm

- Max workpiece length: unlimited

- Grinding heads: 2

- Dimensions: 1435x1100x1510 mm

- Weight: 445 kg

- Max workpiece width: 780 mm

- Max workpiece length: unlimited

- Grinding heads: 2

- Dimensions: 1435x1100x1510 mm

- Weight: 380 kg

Q-FIN TopEdge

TOPEGDE is a manually operated machine for milling various radius or weld edges at various angles. Machine is suitable for edge beveling.

View a brochure: TopEdge

- Max workpiece width: 780 mm

- Max workpiece length: unlimited

- Dimensions: 1435x1100x1510 mm

- Weight: 445 kg

Q-FIN WES

The system of Q-Fin WES (wet extraction system) is made of stainless steel for extraction of grinding dust. WES eliminates the risk of explosion or fire. There are two possible WES types – with capacity 3000 m3/h or 6000 m3/h.

View a brochure: WES