LVD PPED

PPED is a press brake suitable for general purpose bending applications. A robust servo-controlled hydraulic system offers precision and high reliability for consistently accurate bending results. Available 4, 5 or 7 axis PPED models. Working length varies from 2000 up to 4000 mm, and the pressing force from 500 up to 3200 kN.

- Back gauge axis: 2 (X, R)

- Pressing force: from 50 to 320 ton

- Working length: from 2000 to 4000 mm

- Back gauge axis: 2 (X, R)

- Pressing force: from 100 to 320 ton

- Working length: from 3000 to4000 mm

- CNC crowning

- Back gauge axis: 4 (X, R, Z1, Z2)

- Pressing force: from 50 to 320 ton

- Working length: from 2000 to 4000 mm

- CNC crowning

LVD PPEB

PPEB is smart, high accurate press brake with integration of advanced technology and software. The bending capacity varies from 80 to 640 tons, and working length from 2000 to 8100 mm. Back gauge axis – 5 or 8. It is possible to increase distance between table and ram, stroke or gap. PPEB could be equipped with interface for robot connection.

LVD EASY-FORM

EASY-FORM press brakes are smart, highly accurate bending machine trough the integration of advanced technology and software. Bending capacities from 80 tons to 640 tons. Machine is equipped with adaptive bending system EASY-FORM LASER, intuitive and intelligent TOUCH-B control system, CNC crowning system, Linear encoders.

- Axis: Y1, Y2, V, X, R, Z

- Pressing force: from 80 to 640 ton

- Working length: from 1500 to 8000 mm

- Axis: Y1, Y2, V, X1, X2, R, Z1, Z2

- Pressing force: from 80 to 640 ton

- Working length: from 1500 to 8000 mm

LVD DYNA-PRESS

DYNA-PRESS is an electric driven press brake, available with 24 or 40 tons and a working length of 1250 or 1500 mm. DYNA PRESS press brakes are ideal for bending small parts. The electric press drive system delivers fast bending speeds of 25 mm per second.

LVD D-CELL

LVD D-CELL is competitively-priced robotic bending cell. D-CELL makes robotic bending an easy choice for sheet metalworking businesses of all sizes and capacities. The system combines a 50-ton hydraulic press brake with KUKA industrial robot and LVD’s unique programming software.

- Pressing force: 500 kN

- Max part size: 400 x 600 mm

- Min part size 35 x 100 mm

- Max part weight: 4 Kg

LVD DYNA-CELL

LVD DYNA-CELL is a robotic manufacturing cell for productions of small size components. The working speed of bending cell is up to 25 mm per seconds. With DYNA CELL bending cell possible to bend parts up to 350×500 mm (max 3 kg weight per part). It is possible to use a press brake for manual operation. Press brake could bend part up to 1500 mm length.

- Pressing force: 400 kN

- Max part size: 350 x 500 mm

- Min part size 25 x 100 mm

- Max part weight: 3 Kg

LVD TOOLCELL

LVD TOOLCELL press brake is a bending machine with automated tools changer. Optimizing tools setup is fundamental to improving bending productivity. TOOLCELL is equipped with angle monitoring and correction system Easy-Form on board to ensure that all your parts are formed perfectly from the first to the last part.

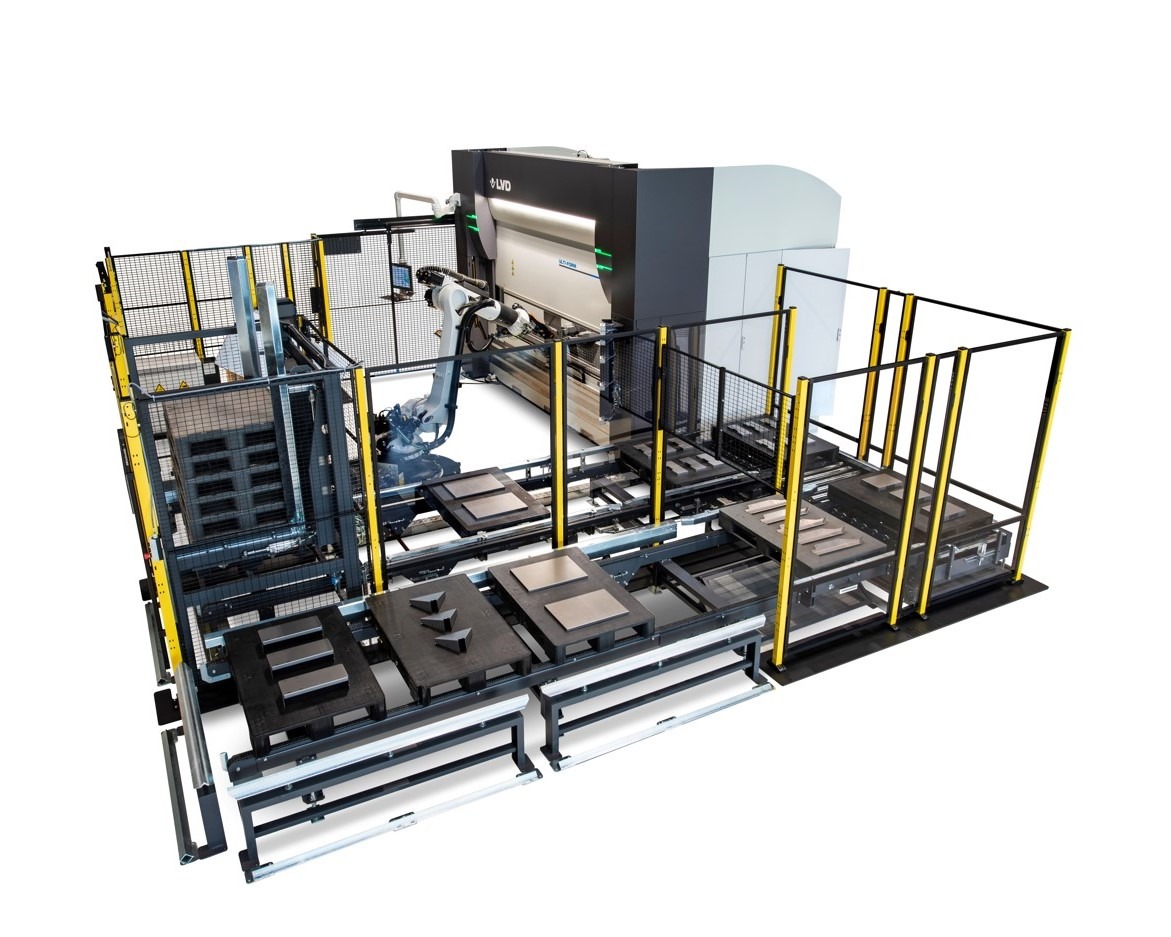

LVD ULTI-FORM

ULTI-FORM is a robotic manufacturing cell that produces medium size components. Bending cell equipped with Easy-form laser; Automatic Tool changer, robot with fast offline programming, one gripper solution, high input for raw material and output for finished parts.

- Pressing force: 1350 kN

- Working length: 3050 mm

- Max part size: 1200×800 mm

- Min part size: 50×100 mm

- Max part weight: 25 kg

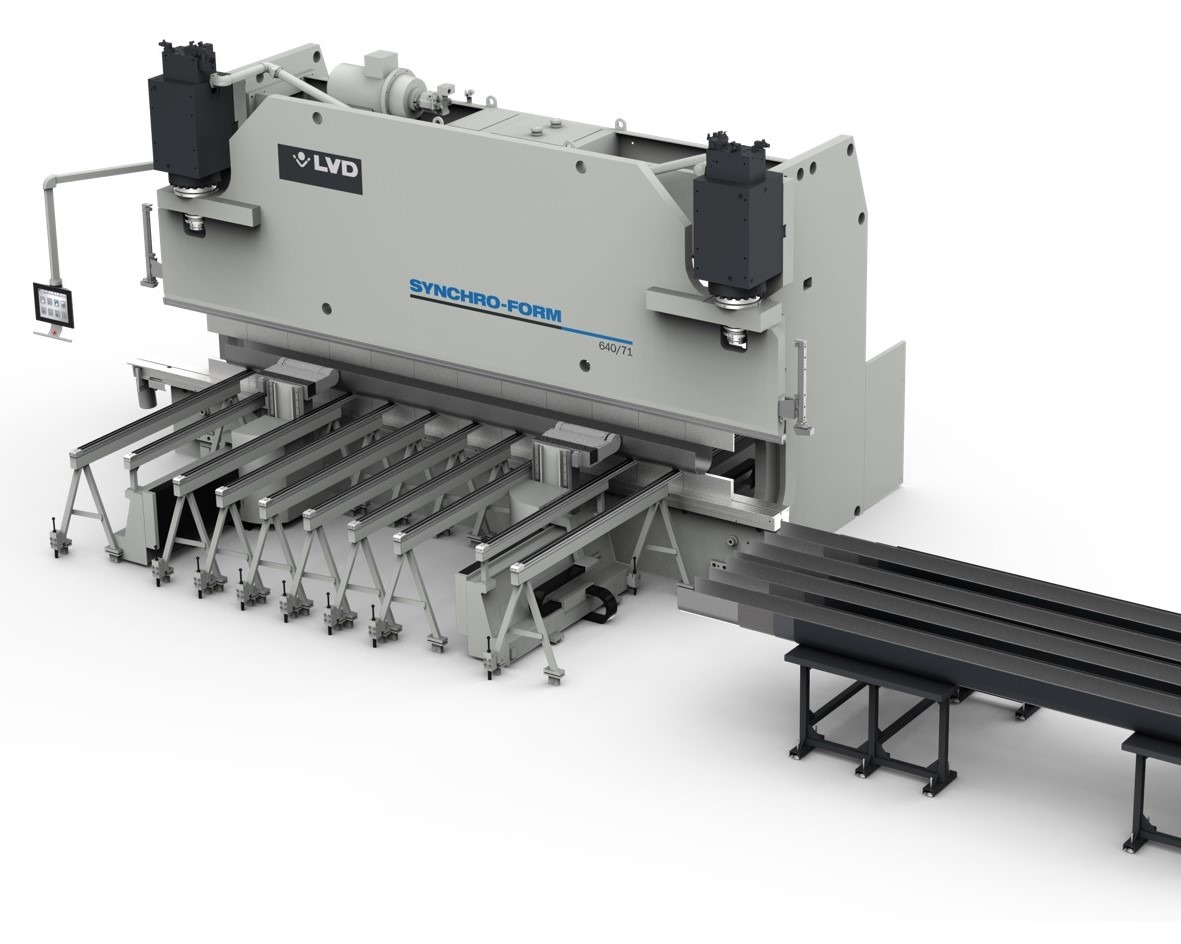

LVD SYNCHRO-FORM

This is a unique bending system for large workpieces. SYNCHRO-FORM eliminates manual operations, reduces setup and handling, and ensures consistent bending results. The digital information is relayed to the LVD TOUCH-B control, which makes adjustments to part and ram position to achieve the correct profile. Variations are not accumulated but compensated within each bend step. So even after multiple consecutive bends, the profile is perfectly formed.

- Pressing force: from 320 tons up to 3000 tons

- Working length: from 4 meter up to 14 meters

- Available in Tandem, Tridem and Quadem configurations