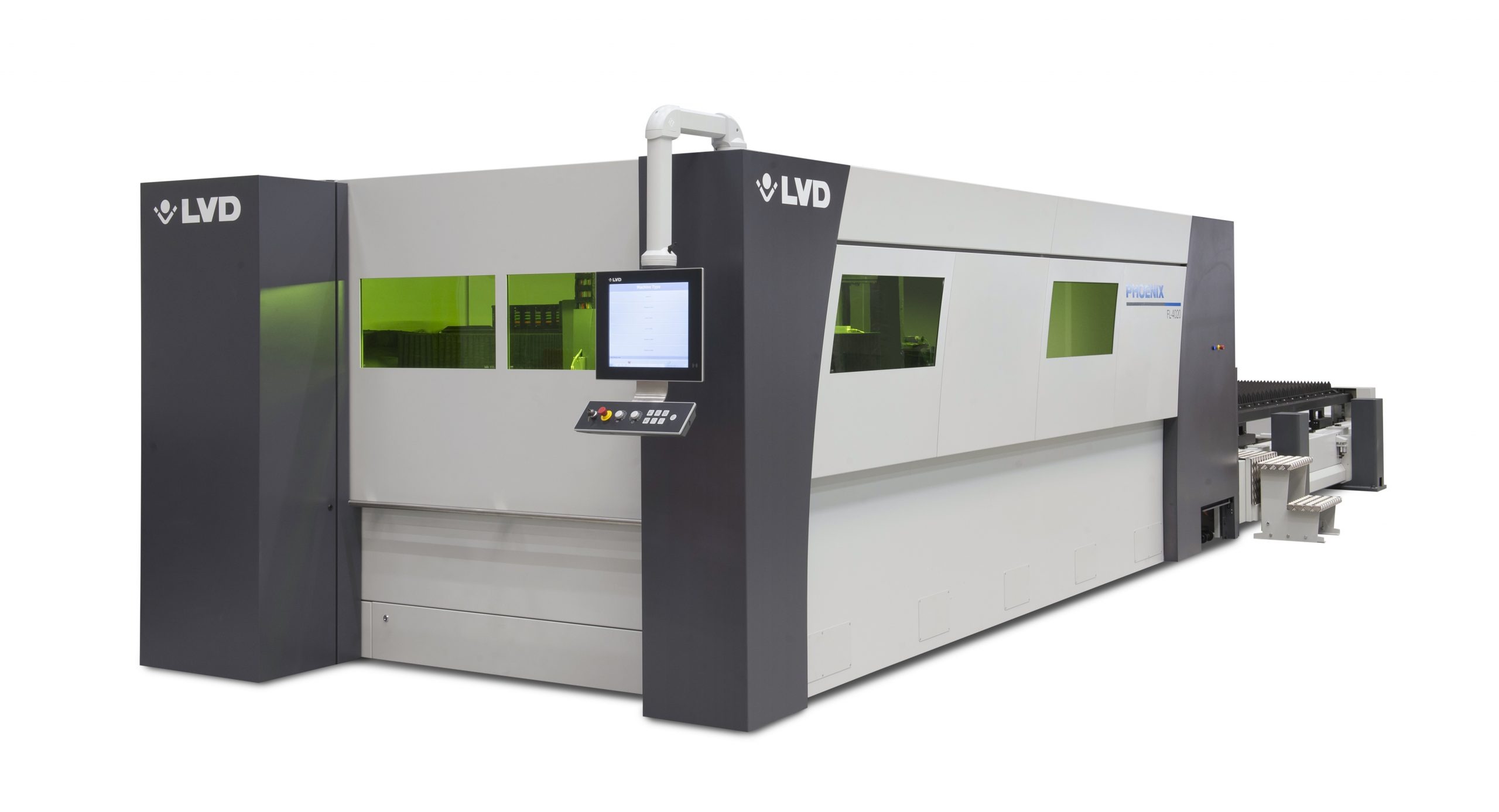

LVD PHOENIX

The LVD PHOENIX laser is fiber laser cutting machine which combines high dynamics with flexibility for cutting thick material. PHOENIX is available in different sizes: 3m x 1,5 m, 4m x 2 m and 6m x 2m. Power source varies from 4kW to 20 kW. As standard machine is equipped with automatic shuttle tables, cutting head, adaptive collimation unit (until 12kW), capacitive height sensing, automatic nozzle cleaning, automatic sheet referencing, automatic cutting gas selection (oxygen, nitrogen and compressed air), chiller and fume extraction, SIEMENS control unit. The PHONEX laser cutting machines are compatible with huge range of automatization solutions such as loading / unloading and sheet storage (up to 6 meters), nozzles changer.

All PHOENIX lasers come with automatic shuttle tables. The height of the table is 930 mm. The speed of table change depends on laser size: for 3015 – 35 sec., for 4020 -39 sec. and for 6020 – 48 sec. Tables on PHOENIX 4020 and 6020 models are split into 2m x 1m modules for easy replacement.

Laser source power on PHOENIX laser cutting machines varies from 4 to 20 KW (available: 4kW, 6kW, 10kW, 12kW, 20kW). The cutting head for 4 – 12 kW lasers could be equipped with 150 or 200 mm focusing lens, for powerful 20kW lasers – 250 mm focusing lens are used.

The PHOENIX 3015 model has a welded steel mono frame construction. This allows high accelerations without losing the accuracy. Due to the high frame rigidity, no special foundations are requested. The frame of PHOENIX 4020 and 6020 exists out of 4 parts. One rigid left and right frame that are connected with two bolted beams.

Options

Automatic nozzle changer with 17 positions.

MOVit Load-Assist automation (LA) offers two systems to increase laser cutting productivity:

- LA Load automatically transfers unprocessed sheets quickly and efficiently to the cutting machine shuttle table.

- LA Load / Unload automatically loads material and, during unmanned production, unloads cut sheets to an unloading station or a conveyor.

Automatic material loading and unloading.

Option available for fiber lasers PHOENIX 3015, PHOENIX 4020 and PHOENIX 6020.

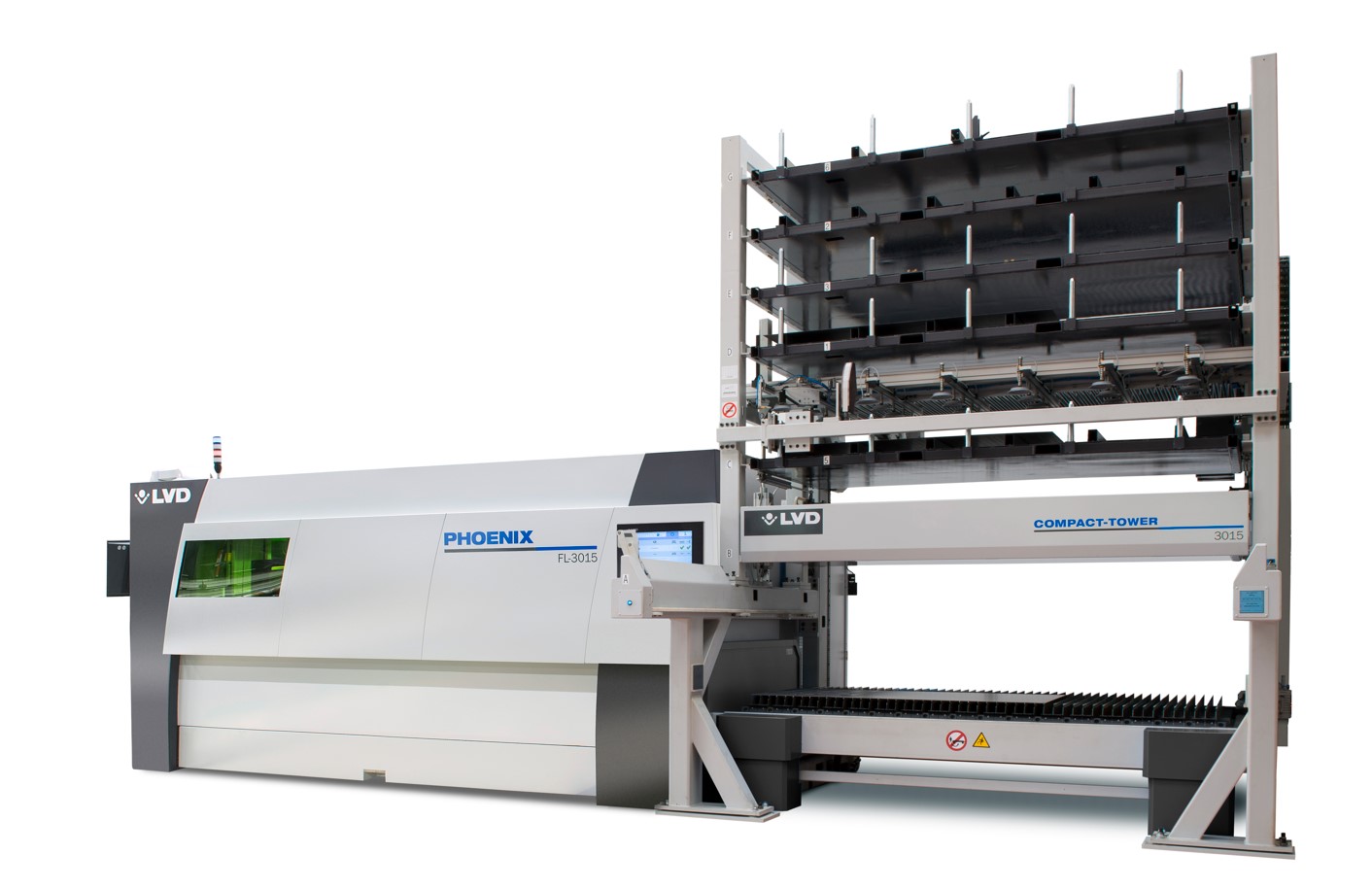

The COMPACT TOWER is a material storage and retrieval tower for 4, 6, 8 or 10 pallets.

Available for fiber lasers PHOENIX 3015, PHOENIX 4020.

There are 16 different TAS configuration possible. The TAS system could be connected with two fiber lasers cutting machines.

- 3-ton capacity per pallet (5-ton for 6020)

- Up to 63 pallets, depending on system configuration

- Stack height – 90 mm

Available for fiber lasers PHOENIX 3015, PHOENIX 4020 and PHOENIX 6020.

- 3-ton capacity per pallet (WAS 3015), 5-ton capacity per pallet (WAS 4020)

- Stack height of 90 mm

Available for PHOENIX 3015 and PHOENIX 4020 fiber lasers.

Abus pilar crane and coval vacuum system.

Specifications

- Max sheet size:

- X-axis travel

- Y-axis travel

- Z-axis travel:

- Max sheet weight on table:

- Table changeover time:

- Max positioning speed X-Y:

- Repetitive accuracy:

- Length:

- Width:

- Height:

- 3050 x 1525 mm

- 3185 mm

- 1560 mm

- 130 mm

- 750 kg

- 35 s

- 140 m/min

- +/- 0,025 mm

- 8825 mm

- 2560 mm

- 3400 mm

- 4065 x 2035 mm

- 4200 mm

- 2070 mm

- 130 mm

- 1600 kg

- 39 s

- 140 m/min

- +/- 0,025 mm

- 13000 mm

- 6300 mm

- 3360 mm

- 6160 x 2035 mm

- 6280 mm

- 2070 mm

- 130 mm

- 2400 kg

- 48 s

- 140 m/min

- +/- 0,025 mm

- 17200 mm

- 6300 mm

- 3360 mm

*excluding light guards, filter and chiller